Machine learning accelerates high-performance materials development

Lawrence Livermore National Laboratory (LLNL) and its partners rely on timely development and deployment of diverse materials to support a variety of national security missions. However, materials development and deployment can take many years from initial discovery of a new material to deployment at scale. Now, an interdisciplinary team of LLNL researchers from the Physical and Life Sciences, Computing, and Engineering directorates are developing machine learning (ML) techniques to remove bottlenecks in the development cycle, thereby dramatically decreasing time to deployment.

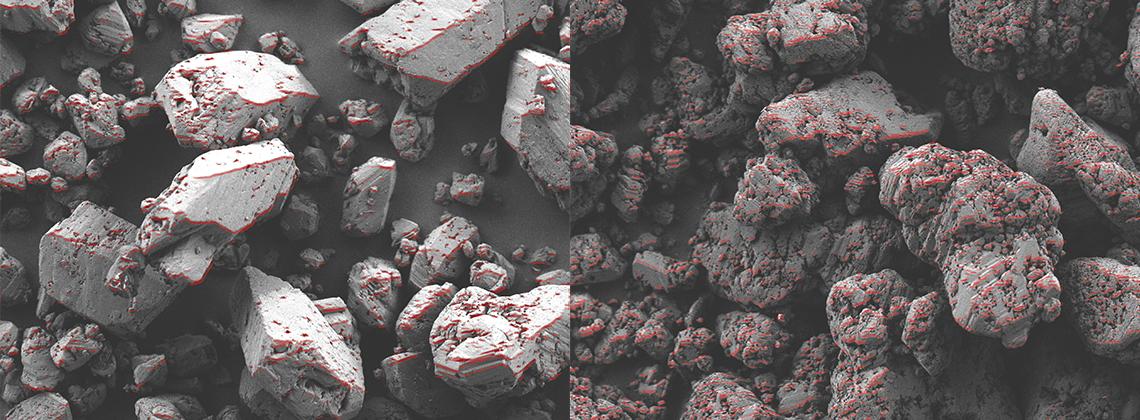

One such bottleneck is the amount of effort required to test and evaluate the performance of candidate materials such as TATB, an insensitive high explosive of interest to both Department of Energy and Department of Defense. TATB samples can exhibit different crystal characteristics (e.g., size and texture) and therefore dramatically different performance due to slight variations in the conditions under which the synthesis reaction occurred.

The LLNL team is exploring the feasibility of a novel approach to predict material properties. By applying computer vision and ML based on scanning electron microscopy (SEM) images of raw TATB powder, they have obviated the need for fabrication and physical testing of a part. The team has shown that it is possible to train models to predict material performance based on SEM alone, demonstrating a 24% error reduction over the current leading approach (i.e., domain-expert assessment and instrument data). In addition, the team showed that ML models are capable of discovering and using informative crystal attributes that domain experts had previously underutilized.

According to LLNL computer scientist Brian Gallagher, lead author of an article appearing in the journal Materials and Design, “Our goal is not only to accurately predict material performance, but to provide feedback to experimentalists on how to alter synthesis conditions to produce higher performance materials. These results move us one step closer to that goal.”

LLNL materials scientist Yong Han, principal investigator and corresponding author of the paper, added, “Our work demonstrates the utility of applying novel ML approaches to address difficult materials science problems. We plan to expand on this work to tackle data sparsity, explainability, uncertainty, and domain-aware model development.”

Team members include Matthew Rever, Donald Loveland, T. Nathan Mundhenk, Brock Beauchamp, Emily Robertson, Golam Jaman, and Anna Hiszpanski. This work was funded by the Laboratory Directed Research and Development Program (19-SI-001).